A mobile sewer flushing vehicle for resource-efficient cleaning of medium to large profile sewers requiring no external energy sources

operational area | usage

- Sewer dimensions ≥ 1,500 mm

- Long pipes

- Long sewer

- Industrial facilities

product description

Currently, the most frequently used cleaning technology for sewers is the combined highpressure flushing and extraction of the sludge-water mixture.

This method is especially expensive in large sewers, it can have a significant impact on the environment and pose threats to health and safety of the operating staff.

By contrast, our newly developed sewer flushing vehicle is characterised by its being autonomous (no external energy source required), emission free and safe.

The RW-S-KSW is used to automatically remove mineral and organic deposits from large sewers with low gradients. It can be used in a either mixed rain and wastewater, or normal wastewater sewers.

The flow of water pushes the vehicle forwards by building pressure at the vehicles rear at a speed of approx. 1–10 cm/min, depending on the quantity of deposit being moved.

By using the potential energy of the upstream water, a fixed, defined flushing wave in front of the cleaning shield picks up the deposits in front of the vehicle and transports them down the sewer.

The deposits are transported for long distances until a suitable point is reached, at which the material can be extracted.

Considering that once the device has been positioned in the sewer, this cleaning occurs entirely autonomously, the vehicle can stay in the sewer for prolonged periods of time.

The cleaning occurs steadily, effectively and without haste until a grit trap aboveground are impeded.

The development was funded by the German Environmental Foundation (Deutsche Bundes stiftung Umwelt).

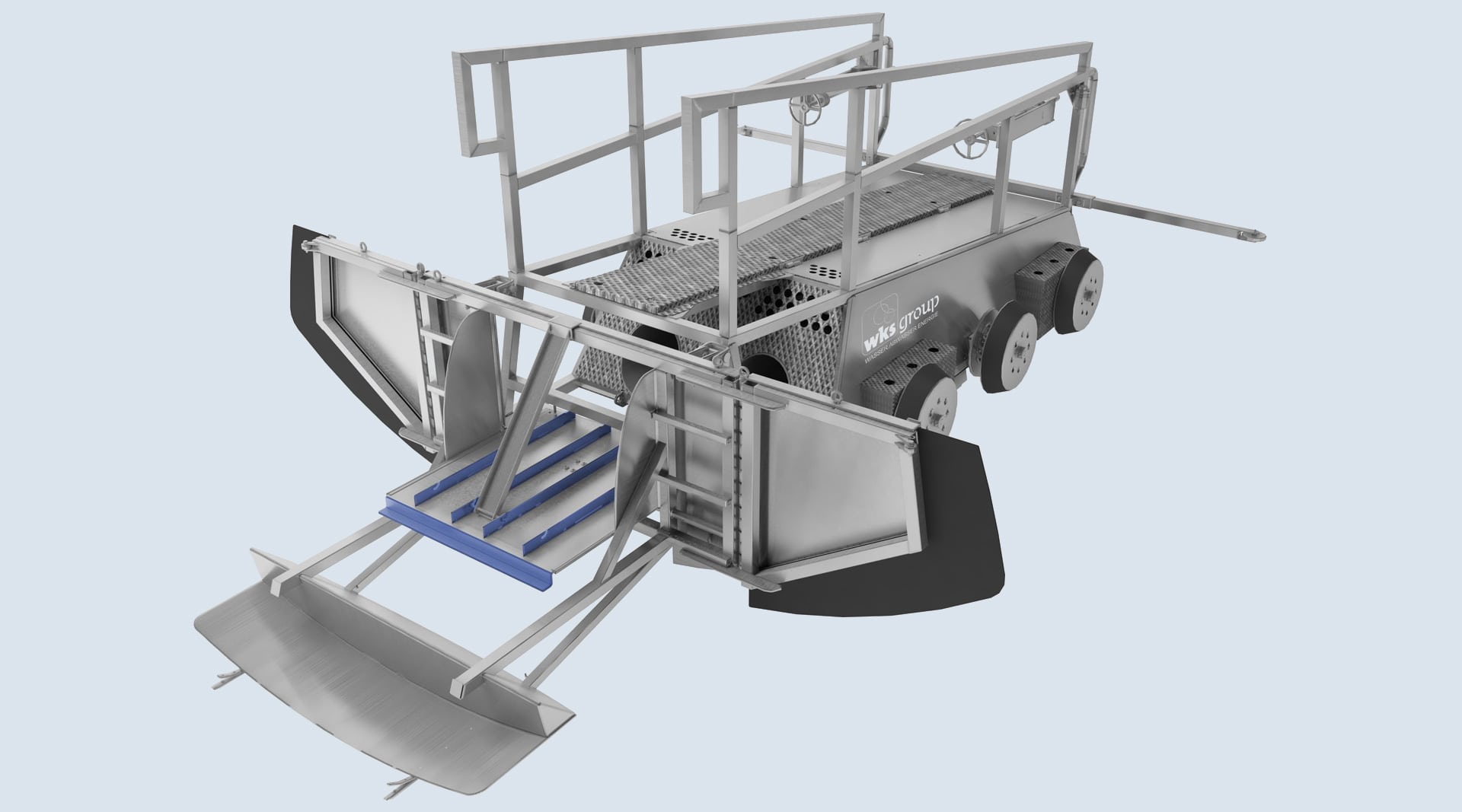

constructional features

- Swivel side flaps for adapting to different pipe cross-sections

- Automatic, controlling overflow flap valves adjusted to water level

- Streamlined design to avoid fouling / entanglement

- Hydraulic negative brake for controlling the cleaning speed

- Modulatable structure for within the sewer

- Stainless-steel construction

benefits

- 100 % environmentally friendly sewer cleaning method (no energy or freshwater consumption needed during cleaning)

- Cost-effective sewer clearance due to low investment and operating costs: 5–10 times more cost-effective than high-pressure flushing

- Long distances can be serviced and the use of suction vehicles is vastly reduced

- Working distance determined by the local circumstances of the sewer network

- Autonomous, automatic sewer clearance

- High operating safety due to unmanned deployment of vehicle

- Compared to jetting methods, no risks of sewer damage

- No obstruction to traffic

- Improved health and safety conditions thanks to reduced risk of accidents