Automatic clean water removal from SBR and sedimentation tanks with compact design for discharge quantities up to 300 m³/h

operational area | usage

- SBR wastewater treatment plants

- Industrial plants with sedimentation tanks

product description

Clean water removal from the sedimentation phase is an important step in the SBR technology process. Following adequate sedimentation of the activated sludge, clean water is separated, without accidental removal of activated or floating sludge.

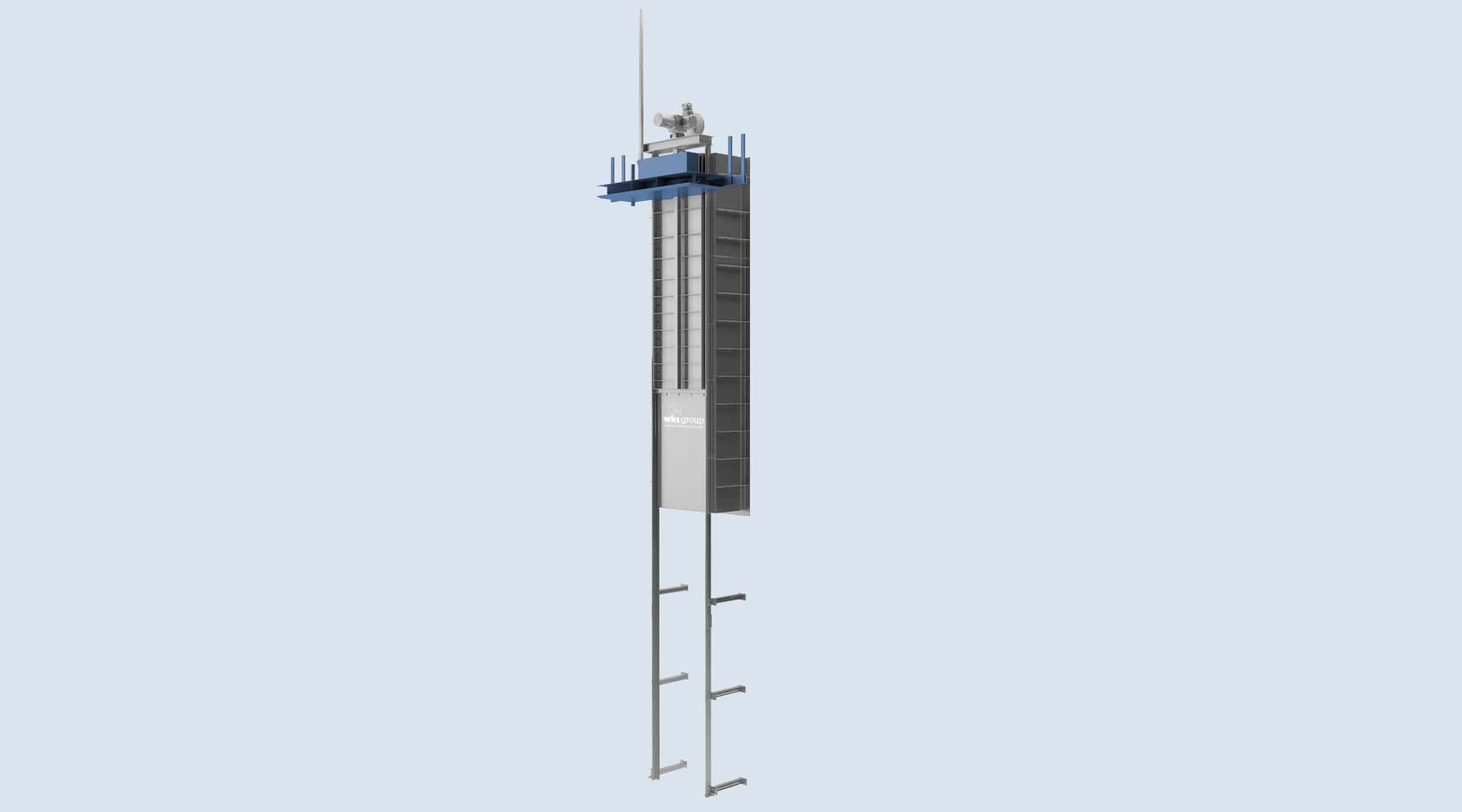

The Hydroklar-Plus is designed as a compact removal system based on a weir type channel penstock with outlet shaft.

Outside of the removal phase, the overflow edge of the gate is located above the water level. The start and end of the removal phase can be set according to a time, level or turbidity regime. The time-controlled or turbidity-controlled start signal switches on the drive motor and the gate is opened via the spindle. The clean water flows over the overflow edge of the gate into the outlet shaft. The scumboard connected to the gate ensures that the floating sludge is held back. The inlet area of the scumboard is designed to ensure horizontal, laminar inflow. In this way it is possible to get very close to the sedimentation boundary and to achieve a maximum exchange volume, without the sludge sediment being swirled up.

On reaching the specified fill level or exceeding the turbidity limit the drive automatically stops and removal is ended. The gate is moved to its top end position or reverts to the turbidity schedule so that it continuously moves ahead of the rising water level.

constructional features

- Preassembled weir type channel penstock with outlet shaft (made of stainless-steel) in compact design is anchored onto the tank wall

- Flow-optimised laminar inlet prevents inlet turbulence

- Front-mounted, floating sludge repelling scumboard

- Controllable electric motor drive

- Control system by time, discharge quantity and turbidity possible

- Dynamic control system simultaneously adjusts the overflow edge to the falling sludge layer

- Heating band surrounds the gate guide (optional)

- Device for sampling within the outlet shaft

- Discharge quantities from 80 to 300 m³/h

benefits

- Simple, compact design with high degree of functional safety resulting in shortening of the removal times and maximisation of the exchange volume

- Sludge barrier prevents the removal of floating sludge

- Turbidity as the control variable results in controlled clean water removal as well as reduced time due to the overlapping of sedimentation and removal time

- Functions as an emergency overflow and can be optionally equipped with heating and sampling

- Easy access for maintenance and inspecting of the discharge

- Can be used with new wastewater treatment plants or can be retrofitted