Eco-effective phosphorous recycling of wastewater containing phosphorous for cost-effective use of the nutrients in agriculture

operational area | usage

- Use in phosphorus containing wastewater (PO4-P > 70 mg/l, PO4-P > 100 kg/d)

- Very effective in combination with anaerobic pre-treatment

- Optional batch or continuous flow operation

- Depending on the MAP quality requirement, various options available for treatment of the separated MAP

Technology | Process

The formation of magnesium – ammonium phosphate crystals (“MAP”, struvite) is achieved by pH adjustment (pH > 8.1), dosing of magnesium hydroxide (Mg(OH)2) and if necessery by adjusting the concentration of ammonium (NH4-N). The tank is shaken up by means of medium bubble aeration which causes intensive chemical mixing as well as extension of the MAP crystal contact time.

To retain the MAP crystals, a parallel plate separator is used at the tank overflow in the continuous flow process. In the batch process the crystals are retained by gravity sedimentation. The demand-orientated ammonium dosing is achieved by determining the ammonium concentration through means of ion-selective measurement. The necessary magnesium dosing is determined by measuring the phosphorus concentration. Positive displacement pumps are used for cyclical MAP removal. MAP dewatering using a screw extruder, in combination with MAP scrubbing to improve the MAP quality (reduction of the mixed suspended solids). Optimisation of the MAP crystallisation is achieved through turbid water return. Use of the RBS-MAP control module ensures optimum efficiency of phosphorus elimination with the lowest possible operating costs.

Process Engineering Components

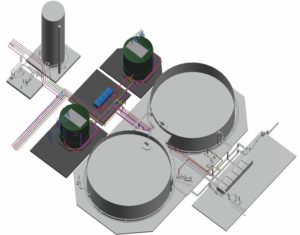

MAP set consisting of:

- Process-relevant equipment of reaction tank (aeration, inlet and discharge system, MAP removal, MAP dewatering)

- RBS-MAP control module for process optimisation

benefits

- Eco-effective phosphorous recycling

- More economical use of supplies through control module for process optimisation

- Reduction in the surplus sludge produced in a downstream aerobic treatment stage (reduced precipitated sludge quantity)

- Increase in the mixed liquor suspended solids of a downstream aerobic treatment stage (clearly reduced precipitated sludge)

- Increase in the operational reliability of a downstream aerobic treatment stage (increase in the sludge age)

- Reduced energy costs of a downstream aerobic treatment stage (ammonium is incorporated in struvite)

- By stripping carbon dioxide, pH is increased without addition chemicals

- Marketing of the separated MAP