Intelligent, dynamic, wastewater load and quantity-controlled SBR technology

operational area | usage

- Municipal wastewater treatment of mixed or separated wastewater system for population sizes from 500 to 300,000 inhabitants

- Industrial wastewater treatment

- Especially suited to industrial wastewater treatment in combination with MAP precipitation and anaerobic pretreatment

- In combination with wks dosing technology

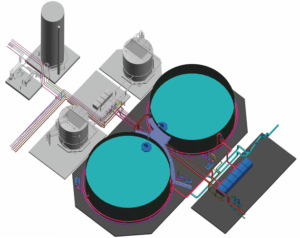

- One to 4-lines, optional in combination with inlet / discharge storage tank, adaptable to plant size

Technology | Process

The SBR process is a form of activated sludge process. The spatially separated functional components of a conventional aeration plant are implemented in phases within the same tank SBR (Sequential Batch Reactor) process. Wastewater treatment takes place during the reaction phase. During the subsequent sedimentation and decanting phase the activated sludge is separated from the treated wastewater. Depending on the wastewater to be treated, the aeration is implemented through fine bubble pressure aeration or ejector aeration. The tank contents are shaken up either by pulse aeration, horizontal agitators, ejectors or by means of vertical agitators mounted on the clean water decanter. Depending on the overall configuration, batch charging to improve the sludge settling properties and biological phosphorous elimination are possible.

The innovative key point of wks SBR technology is the intelligent, dynamic and load-dependent control of the process phases and technical system with turbidity-controlled clean water removal, water level-dependent vertical agitator and automatic floating sludge

removal.

Clean water removal follows the phase boundary layer of clean water /activated sludge phase, in this way the sedimentation and decanting phase is limited to a minimum.

Process Engineering Components

- HydroSys equipment system with:

- AW-HydroMix vertical agitator

- AW-HydroDek clean water removal (decanter)

- AW-HydroKlar PLUS optional clean water removal

- AW-ASSS floating sludge removal

- Automation technology incl. RBS-SBR control module for process optimisation

- Energy-optimised aeration system

benefits

- By using the RBS SBR control system the plant operates economically, and at optimum performance

- Maximum possible nitrogen elimination at optimised operating costs and energy use

- Extensive biological phosphorous elimination

- Prevention of unwanted phosphorous redissolution at the end of the reaction phase

- Turbidity controlled, extensive and laminar clean water removal

- Precisely matched functional characteristics of the components for an optimum process workflow to ensure the specified effluent discharge values

- Reduced energy cost